fabco-air

MULTI-PISTON HIGH FORCE ACTUATORS Multi-Power® - Fabco-Air

MULTI-PISTON HIGH FORCE ACTUATORS Multi-Power® - Fabco-Air

No se pudo cargar la disponibilidad de retiro

Share

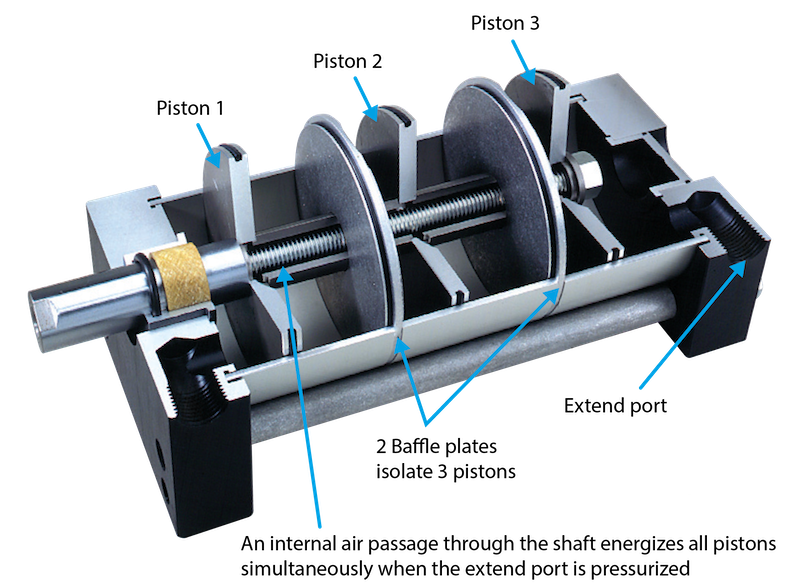

Multi-Power® actuators are an ideal choice when you need tremendous thrust from a modest amount of shop air. Designed with multiple pistons connected to a single rod, they provide greater force output while taking up less space than conventional cylinders with larger bores. Not only do they provide impressive thrust in a compact size, they use a mere 100 psi of shop air and do not require a high-pressure hydraulic system. And Multi-Power actuators require only one piston for the return stroke, economizing air volume.

Additional features include a clear-anodized aluminum outer diameter and a hard-anodized aluminum inner diameter, hard chrome-plated stainless steel piston rods to ensure reliable operation and pre-lubrication with Magnalube-G® grease for long life. Multi-Power air cylinders come in 10 bore sizes from 1 ⅛ to 12 inches, a choice of two, three or four stages and are available with strokes up to 12 inches.

The Multi-Power Principle is a novel design concept in which multiple pistons are attached to a single rod that has integral air channels. The multiple pistons create a larger collective surface area for the air pressure to act on, while pistons are pressurized simultaneously. The result: extraordinary thrust forces at the cylinder rod. Unlike other common methods of increasing the thrust forces of an air cylinder, the multi-piston design doesn’t require increased air pressure or a larger cylinder bore size. This gives you maximum power from the smallest footprint possible. In fact, Multi-Power cylinders can achieve forces up to 22 tons with only 100 psi of shop air. The cylinders also use just one piston to retract, which can allow 22 to 37% air savings.

FEATURES

- 10 bore sizes from 1 ⅛ to 12 inches and strokes to 12 inches

- Composite rod bearing for longer life

- Prelubed with Magnalube-G® Teflon grease

- Chrome-plated stainless steel piston rods

- Available in two, three or four stages at 150 psi, with additional stages at lower pressure available

- Uses only one stage to return, saving air volume

- Front face-rear face-foot-extended tie rod mounts

- Many options to choose from

- Magnetic piston sensing available

TECHNICAL ADVANTAGES

- Multiple pistons attached to a common rod with internal air passengers produce tremendous forces.

- Forces up to 22 tons can be reached with only 100 psi of shop air.

- The need for a bulky, larger bore cylinder or high-pressure hydraulics is eliminated.

- Hard chrome-plated stainless steel piston rods ensure long cylinder life.

- The cylinder’s clear anodized aluminum outer diameter has an attractive appearance and also resists corrosion.

- The cylinder’s inner diameter is made of hard-anodized aluminum to resist corrosion and exhibit low internal friction.

- Lightweight aluminum piston construction and secure piston assembly ensure precise concentricity for smooth cylinder operation.

- The piston rod-bushing is extra long and rigid. Its non-metallic high-performance composite material ensures reliability and long life.

- High-performance composite resists corrosion, moisture and temperatures up to 325° F, while offering a high load capacity and very little friction.

- Magnalube-G® Teflon-impregnated grease provides a long operating life and lubricates across a wide temperature range.

- Buna-N O-rings are internally pre-lubed with Magnalube-G as standard.